Steel House Stumps: Why They’re Replacing Timber in Modern Australian Builds

Transcript

OK, let’s unpack this. We are literally going to the foundation of what makes a home stand up and more importantly, stay standing for decades. Right. We are talking about that critical yet almost entirely unseen component of any Australian home. Yeah. The humble house stump.

It’s so easy to focus on the flashy things you know the roof tiles or the kitchen finish of course but what’s happening underneath the floorboards is the true measure of a building’s longevity we’ve been reviewing material focused on a massive engineering transition huge shift a huge one the shift from traditional timber supports to these high strength adjustable steel foundation systems and our goal in this deep dive is really to shortcut your learning curve

We want to understand the fundamental differences, the structural metrics, and most importantly, the long-term financial benefits that are driving this change. And it’s not just a marketing trend. No, that’s what’s fascinating. Not at all. This foundational shift is mandated by performance. When you compare the engineering specs, you realize you’re choosing between a material that requires constant management and one that is designed to be virtually maintenance-free. The data unequivocally supports it.

I think most people when they hear house stump, they just picture a block of wood on a concrete pad. So before we compare them, let’s define the modern solution. What exactly are we calling a steel house stump?

Well, essentially, they are the structural supports that connect your home’s main frame, the subfloor, right down to the ground. OK, so they’re stabilizing the whole structure. Exactly. And crucially, they aren’t just raw posts. They are typically fabricated from high strength, hot dip, galvanized steel, and their core function is load distribution. They take the massive weight of the home and transfer it evenly and reliably down into the soil.

So they’re the critical link. I did notice in the sources, there’s sometimes called steel stump footing systems. Is that just terminology or is it more of an integrated system?

It implies a system. Yeah. While the stump is the vertical post, the overall system includes the footing, the base, and the connection mechanisms to the floor bearers. It’s an interconnected unit. So it’s not like a simple timber post that’s just cut to length and stuck in place. Precisely. And this choice of material and system, it really defines the life of the home. It’s critical whether you’re building new or undertaking a huge restumping project.

That brings us to the historical norm then. Timber stumps, they’ve supported Australian homes for over a century. Why are they suddenly falling out of favor? It all comes down to vulnerability and lifespan. Timber, even pressure-treated timber, is an organic material. It’s subject to biological decay. And that becomes a huge liability when it’s constantly subjected to ground moisture and temperature changes under the house.

And the lifespan figures are, I mean, frankly, shocking for someone putting their life savings into a home. Yeah. We found that older timber stumps might only last about 15 to 20 years. That’s right. That’s a very, very tight operational window. It is. And the failure mechanism is predictable. You’re dealing with three major threats. First is rot caused by moisture. Second is general moisture damage, which leads to warping and splitting. And the third one, I’m guessing, is termites.

The third is the biggest dread for any homeowner. Termite attack. Of course. They don’t care how nice your kitchen is. They’re going straight for the structure. Exactly. And once termites get in, the integrity just degrades so rapidly. And homeowners often don’t notice the decay until they see the secondary signs. You know, the cracked plaster, sticking doors. And by then, the damage is already significant. At that point, the required intervention is massive. Which means timber requires continuous monitoring. It’s not a foundation you can just install and forget about.

No, you need regular, sometimes annual inspection for decay, for water logging, for pest activity. And that ongoing inspection costs money. Yeah. And it introduces a lot of anxiety. It does. The moment you move to steel, you just eliminate those traditional biological failure points that have plagued homeowners for generations.

OK, let’s transition into the engineered case for steel. If timber’s lifespan is 15 to 20 years of constant vigilance, what does steel offer? Obviously, steel doesn’t rot. It doesn’t warp. It’s impervious to termites. But what about rust? What’s the big question, right? Yeah. Foundations are often damp. How do you stop steel from just corroding away?

That is the critical engineering detail. It all comes down to a process called hot dip galvanization. Okay, hot dip galvanization. What does that actually mean? Is it like a super tough paint? It’s much more than that. Instead of just painting the steel, which, you know, can chip or wear away. Which is just a surface layer.

Exactly. The components are actually submerged in a bath of molten zinc. And this creates a metallurgical bond, effectively coating the entire piece of steel. So it’s not superficial. It’s fused to the steel itself, a permanent shield. Precisely. And the zinc coating acts as what engineers call a sacrificial anode. A sacrificial anode. Yeah. So if the coating gets scratched, the zinc corrodes first, sacrificing itself to protect the steel core underneath.

This mechanism just drastically slows down corrosion and ensures the stump retains its integrity for decades. It virtually eliminates those maintenance needs. So you’re basically buying a structural element wrapped in a self-sacrificing suit of armor. That’s a huge difference. Now, let’s look beyond durability to actual strength. Modern homes are heavier, more complex. Can steel just handle more load than timber? Oh, absolutely. Steel has an inherent structural superiority.

It’s designed and manufactured to precise load calculations, and it’s engineered to meet or exceed stringent Australian building standards. So you get predictable performance. Exactly what modern construction demands. We mentioned some specific metrics earlier. Uplift, lateral stability, and load distribution. Can you break down uplift for us? It sounds like something you’d only worry about in a cyclone.

It is crucial in cyclonic zones for sure, but also in areas with highly reactive clay soils. Uplift is the force trying to pull the house up off its foundation. High winds can do it, but so can soil movement. When clay soil gets waterlogged, it swells. And when it dries out, it shrinks, creating massive pressure. So the foundation isn’t just holding the house down. It’s fighting the ground’s urge to push the house around.

You’ve got it. Steel, because of its tensile strength and engineered connections, just outperforms timber in resisting that upward force. And lateral stability, that side to side movement.

Right. A well-engineered steel system ensures the entire subfloor acts as a rigid diaphragm, keeping the structure plumb and level even on a sloping block. This is why engineers specify it. That structural confidence must be a massive selling point for builders. And that leads to what I think is the most fascinating feature, the sheer practicality of adjustability. What does micro adjustable actually mean for a foundation?

This is perhaps the single biggest innovation. Older foundations, timber or concrete, are set in stone, so to speak. Right, they’re fixed. But systems like these adjustable steel stumps have integrated mechanical parts, often a big screw thread, that let installers minutely raise or lower that specific point of support. How many meters are we talking? Are we talking a few centimeters? We’re talking millimeter precision. It’s incredibly fine. But the genius isn’t just for the initial installation. It’s the long-term maintenance.

Because of that reactive soil we mentioned. Exactly. Even the best built home will see some settlement over its lifespan as the ground shifts and compacts. OK, so say you have a timber stump and the house settles five millimeters on one corner. What’s the fix?

The fix is major structural work. You have to lift the house, remove the sunken stump, replace it. It’s disruptive. It’s expensive. It’s a huge headache. But with micro-adjustability. It transforms that headache into a calibration process. A professional can get under the house, identify the spot, and use a tool to precisely turn the adjustment mechanism. They can re-level the home without any major disruption. So it’s like a built-in suspension system for your house that you can tune over time.

That’s a great way to put it. It’s a huge structural insurance policy for the homeowner. That makes perfect sense. Now, what about the construction timeline? Builders love anything that speeds up a project. How does steel compare to, say, traditional concrete piers?

It’s significantly faster. With concrete, you have excavation, you have pouring, and then you have the crucial waiting period, the curing time. Right, you can’t build on it straight away. No, concrete takes days, sometimes weeks, to achieve the necessary strength. This just introduces massive delays. And delays mean money. Precisely. Steel stumps are manufactured off-site. Once the footing is ready,

The steel system can be installed, leveled, and immediately loaded. It shaves valuable time off the construction schedule. So builders get consistency, predictable performance, and faster installation. I can see why it’s becoming the default, especially on those challenging sites with uneven terrain or reactive soils.

It’s all about minimizing risk and maximizing consistency. Builders trust it because the components are manufactured to precise tolerances. They know exactly what load they can carry. There’s no guesswork? None. The confidence is rooted in the engineering specs and the structural certification that comes with them.

We have to talk about the elephant in the room here, which is always the cost. Because steel stumps, they do have a higher upfront cost than their timber counterparts. Well, they absolutely do. The galvanization, the engineering, the material itself, it all adds up to a higher initial price tag. If you’re just comparing material costs on day one, timber looks cheaper.

That initial price has to be a barrier for some. So why financially should a homeowner make that leap? It’s the classic difference between cost and long term value. Let’s look at the financial lifecycle. If you install timber today, you are almost guaranteed to need a major restumping project in 15 or 20 years. And that involves?

What? Lifting the house. It involves excavation, structural disruption, often jacking up parts of the house. It is enormously expensive, far more expensive than the initial savings you made by choosing timber. So you’re basically paying twice, maybe even three times over the 50 year life of the home. Exactly.

By choosing engineered steel you are eliminating that massive future expense it’s cheaper over the entire life of the home you’re investing in minimizing future risk that reframes the decision completely it’s not an expense it’s risk management that’s the core takeaway okay let’s shift focus to the listener who already owns a home maybe they’ve got older timber stumps and they’re worried what are the key warning signs that their foundation might be failing what should they look for

There are four specific observable signs that every homeowner should be vigilant about. Catching them early is paramount. Give us the list. What’s number one? The first and most obvious is unexpected cracks in the internal walls or floors. Especially watch for those diagonal cracks that run out from door and window frames. OK, cracks. What’s the second? Second, you might notice uneven or sloping floors.

That’s a classic indicator that part of the house has settled lower than the rest. You might feel it when you walk across the room. A definite sign of movement underneath. What’s number three? Third is functionality. Doors and windows that suddenly start sticking or won’t close properly when they used to. That means the frame has racked out of square because the foundation has moved. And the final one, I’m guessing, goes back to the timber itself.

It does. The fourth sign, particularly in older properties, is noticing dampness or seeing visible rotting timber under the house. That’s the material feeling, and it’s often a sign that termites might be present too. So if you see any of those four signs, get a professional assessment. Immediately.

Absolutely. Foundation problems never fix themselves. They only escalate in severity and in cost. That’s incredibly practical advice. OK, let’s bring this to a synthesis point. What’s the core message we want the listener to take away about foundation choices today?

The core finding is that for any modern Australian build, especially on uneven or reactive soils, steel house stumps are the demonstrably superior, durable and low maintenance solution. Right. They eliminate the most common failure points, the rot, the pests, the warping, and provide reliable engineered support that’s designed for longevity. And that reliability plus the adjustability, it fundamentally changes long term homeownership by basically buying out the future risk of a huge foundation repair bill.

It’s an investment in structural certainty. But I want to reiterate one key requirement. Quality assurance is paramount. Any system you choose must be engineered. It must comply with Australian standards. And crucially, it must offer structural certification. That certification is your proof of performance. It is. It’s your proof that the load capacity and the galvanization meet the specifications. It’s non-negotiable.

A certified structure is a secure structure. Thank you for guiding us through the critical world beneath our floorboards. Now, as we wrap up, there’s a fascinating element tied to this. Given the speed and precision of these modern systems, what opportunities does this engineering shift open up for the future of rapid construction, specifically in the growing market of modular and kit home builds, particularly in Australia’s most geographically challenging and remote environments? That’s a powerful thought to mull over until our next deep dive.

In Australian home construction and restumping, choosing the right foundation support material is a critical decision. While traditional timber house stumps were once the norm, steel house stumps are increasingly becoming the preferred option for both new builds and restumping projects.

This shift isn’t just trend-driven; it’s backed by long-term performance benefits that matter to builders and homeowners alike.

What Are Steel House Stumps?

Steel house stumps (also called steel stump footing systems when combined with footing components) are structural supports made from high-strength, usually hot-dip galvanised steel, installed beneath a home’s frame to distribute load evenly to the ground. Unlike timber, they do not rot, warp, or succumb to termite damage, offering a strong, low-maintenance alternative for house foundations.

Timber vs Steel House Stumps: A Straightforward Comparison

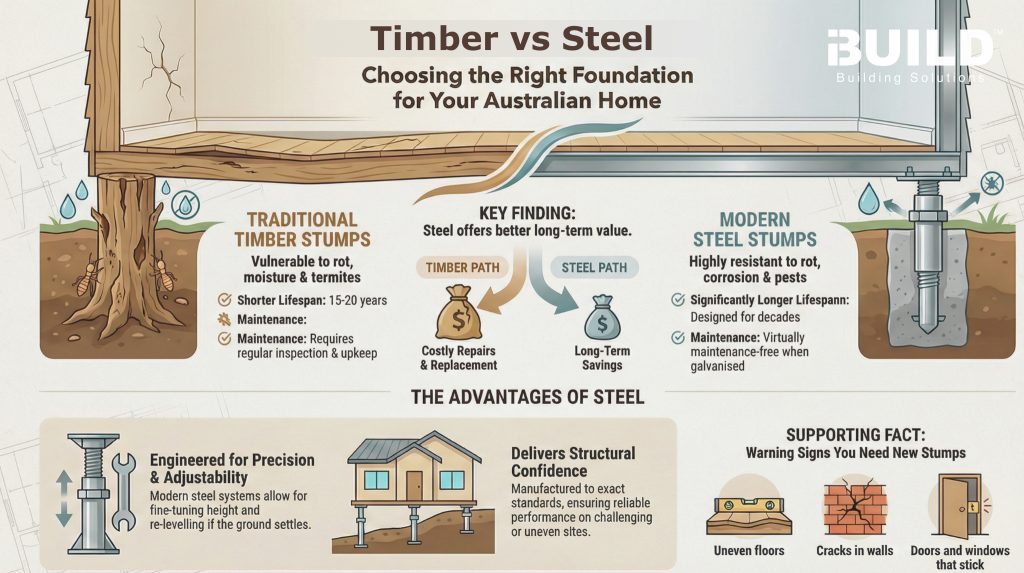

Durability & Lifespan

Timber stumps have historically been used in Australia, but they are vulnerable to rot, moisture damage, and termite attack, which can significantly shorten their lifespan. In some regions, untreated or older timber stumps may only last ~15–20 years before needing replacement.

By contrast, steel stumps do not rot or warp, and when galvanised, the zinc coating protects the steel from rust and corrosion, greatly extending usable life and reducing long-term maintenance needs.

Strength & Engineering Performance

Steel’s inherent strength and load-bearing capacity make it ideal for modern builds where precision and structural reliability are key. Steel stumps can support heavier loads and are engineered to meet stringent building standards, often outperforming timber in uplift, lateral stability, and load distribution.

Maintenance & Longevity

Timber stumps require regular inspection for pest damage and moisture-related decay. Steel house stumps, when galvanised, are far less maintenance-intensive, resisting pests and environmental wear, which translates into fewer replacement cycles and lower lifetime costs.

Cost Over Time

While steel stumps generally have a higher upfront cost than timber, their longevity and resistance to failure factors such as rot and pests often make them cheaper over the life of the home. Reduced need for restumping or repairs means better value in the long run.

Why Builders Prefer Steel House Stumps

Adjustability & Precision

Systems like iBuild’s Adjustable Steel Stumps, engineered with hot-dip galvanised components and micro-adjustable mechanisms, allow installers to correct height variations easily and re-level the home if settlement occurs over time. This flexibility isn’t available with fixed timber stumps.

Quick Installation

Compared to concrete alternatives, steel stumps can be installed more rapidly, reducing labour time and site disruption.

Structural Confidence

Because steel components are manufactured to precise tolerances and engineered to specific load calculations, builders trust them for consistent performance, critical when building on challenging sites with uneven terrain or reactive soils.

When to Replace Existing House Stumps

Signs your home might need new stumps (whether timber or steel) include:

- Cracks in walls or floors

- Uneven or sloping floors

- Doors and windows that stick or don’t close properly

- Damp or rotting timber in older subfloors

Are Steel House Stumps Worth It?

For modern Australian builds, especially houses on uneven or reactive soils, steel house stumps offer a durable, low-maintenance foundation solution. They eliminate many of the failures associated with timber stumps, such as rot and pest damage, and deliver reliable support designed to last decades.

While initial costs are higher, the longer lifespan and reduced maintenance often justify the investment for homeowners and builders alike.

When selecting a supplier, look for engineered systems that comply with Australian Standards and offer structural certification.

iBuild’s Adjustable Steel Stumps, designed and certified in Australia, meet these engineering requirements and integrate seamlessly with modular and kit home builds.

The foundation is one of the most important parts of any home, and choosing the right support system is a long-term decision. Steel house stumps are increasingly replacing timber in modern Australian builds because of their strength, durability, resistance to decay and pests, and long-term value. For homeowners who plan to stay in their homes for many years, and for builders who value predictable performance, steel stumps are often the smart choice.

Explore iBuild’s engineered Adjustable Steel Stumps for certified, Australian-standard support systems designed for long-term performance.